Our Process

Need something custom for your product line? We’re an experienced partner from design to production.

We can help design and produce buckles, swivel snaps, closures and many other hardware items made from low-lead brass, as well as zinc, stainless steel, iron or other metals. For all custom manufacturing projects we work closely with our customers from start to finish to ensure a finished product that exceeds expectations.

Step 1: Consultation

Our first step with new customers is a free consultation to learn more about the hardware needs for the products being developed. With decades of industry experience we are here to provide input.

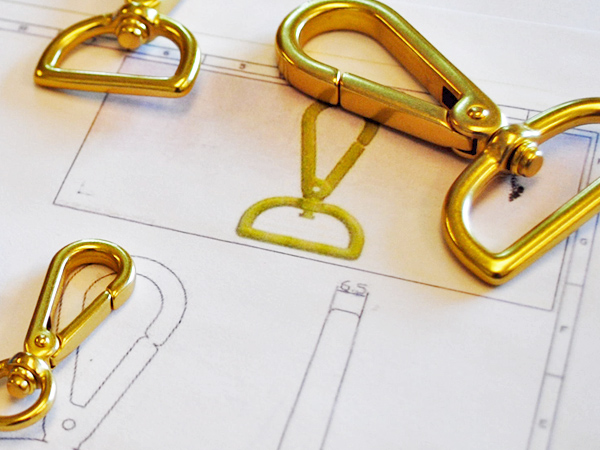

Step 2: Initial Design

After our initial consultation we begin developing the initial designs of the hardware. Customers provide us with anything from simple sketches, to CAD drawings or physical samples.

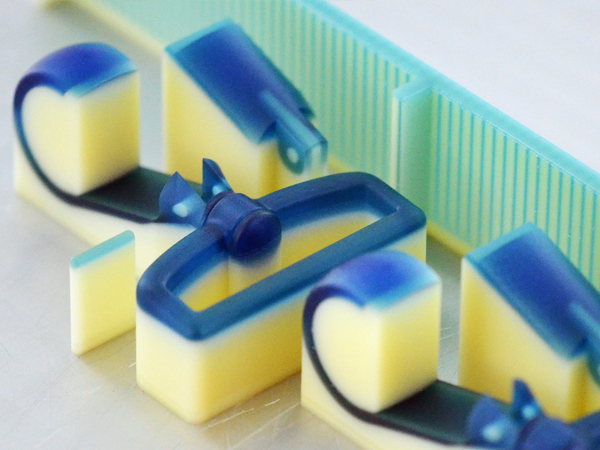

Step 3: 3D Samples

Whether you provide us with physical samples to match, or simple sketches, we use these to develop 3D drawings called STL files. We use these STL files to print plastic samples from our 3D printer in Massachusetts.

Step 4: Final Samples

After the initial plastic samples are approved we move to final product sampling. These will be used as the pre-production samples from which the father mold is created.

Step 5: Production

Once the final samples are approved we move to production. Our factory has the capacity to handle both large and small scale production runs.

Step 6: Delivery

The hardware is packed and can be directly delivered anywhere in the world. We can also ship via ocean containers from our facility in Asia direct to our Massachusetts warehouse at no cost to you.